Base for fabric sewing that supports product competitiveness | World Industry Fabric Okayama Institute of Technology

Introducing World Industry Fabric from the World Group team introduction "OURTEAM" (From an article in the World Group internal newsletter on April 15, 2022)

WORLD INDUSTRY FABRIC handles not only the brands within the World Group, but also various brands of other companies as a production platform.

Okayama, which was established in 1978 among the 6 domestic companies and 8 factories of the World Group, has strengthened human resource development and the uniquely developed system WPN (World Production Navigator), and provides technical guidance to overseas factories as a base for fabric factories that boast high technology. Also do

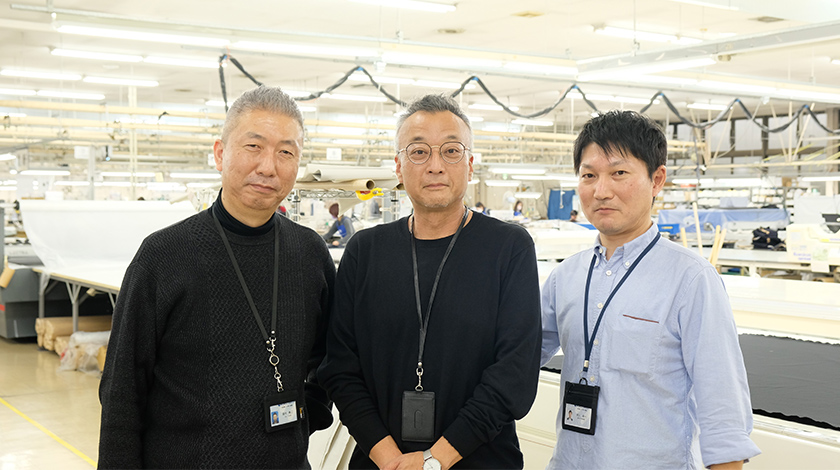

We will deliver an interview with three members who support manufacturing.

I would like to increase the number of drawers that can handle high-mix low-volume production by accumulating experience. Manufactured by Ayami Tsushima

I joined the company mid-career, and this January marked my third year. I used to like working with my hands, but it was just a hobby. What I am currently doing is mainly watching the sewing of the front body and back body as a supporter of the line. We will adjust the progress so that the number of arrivals reaches the daily goal.

Right after I joined the company, it was a time when I was sewing medical gowns due to the corona disaster. After that, I learned the work while being taught by everyone, and now I am responsible for managing the progress of the line as a supporter. The process changes from time to time, so while watching the overall progress, I make adjustments so that the members do not have to waste time in the subsequent processes, and check the finish to see if it is sewn correctly. It is a check to see if there are any mistakes in the stitching or if there are any defects. If you proceed with the defect, you will have to make corrections, which will lead to losses.

Anyway, I'm full of things in front of me, but I'm happy and relieved when the line flows smoothly. The line usually sews jackets, but today I am working on a dress. There are various fabrics, and the design itself can be difficult.

Since we are dealing with a wide variety of products, I would like to learn more and increase the number of drawers, such as "If something like this happens, how to deal with it."

Accuracy is important in order to proceed to the next step. Pattern Mr. Sakiya Tani

I'm from Osaka, and after graduating from fashion school, I joined World Industry Fabric as a new graduate, and I'm in my second year. My current job is to first check the patterns that come from the brand, add shrinkage ratios, and add seam allowances according to the specifications. It does not change the original shape, but the width of the seam allowance is necessary for the attachment (sewing machine presser foot, winding tool, etc.) to be used for sewing later, for example, for three rolls. Make adjustments such as adding a wider seam allowance.

The pattern is measured once with the data on the screen, and after a thorough check, it is output on paper. In the end, I use paper to align all the notches (marks to align the parts when sewing), and check each one to make sure there are no leaks. Then, we create specifications and process analysis for each model. In the process analysis, we look at the order in which the parts are assembled on the line and give a rough time. Estimate the time in seconds to sew this straight line of this length, for example, referring to the data so far.

This work is very detailed, as even a single notch in the pattern can be misaligned. There are different types of notches, and they are used according to specifications. After all, it makes me happy that the samples and products that I was involved in are beautifully finished after repeated detailed confirmations.

We listen to the thoughts of designers and pattern makers and put them on the mass production line. Pattern Kayo Yoshida

When I was a student, I never thought I would work in a factory. However, when I was recommended by a teacher during my time at a vocational school and went on a tour, my image was completely different. When I saw a sample being sewn, I became interested in the process of creating it while having meetings, so I joined the company, and am now in my 19th year.

After joining the company, I also worked on the sewing of each color sample line and small lot samples. At that time, I sewed more samples than I do now. After that, I was involved in the trial at the time of WPN introduction before moving to my current role. In the meantime, I also work in technology development at the Kobe head office.

The core of my current work is communicating with and making proposals to brands. Each pattern maker gives shape to what the designer wants to create, but in order to draw out the intention from that and actually mass-produce it, we sometimes propose, "If you want to finish like this, this is better," along with samples of partial stitching. It's a worthwhile job, taking into account the efficiency of mass production.

When I joined the company, I handled a lot of jackets such as recruit suits, and I was sewing the same cashmere coat for a month without switching. The number of sheets was completely different from that time, and the materials themselves have evolved and the number of difficult ones has increased. I myself grew up while being taught by many seniors, so I want to pass on my experiences to the next generation.

Focusing on human resource development and realizing a QR system with high technology

All World Group factories have the “J Quality” certification (certification that indicates genuine Japanese apparel). promoting acquisition.